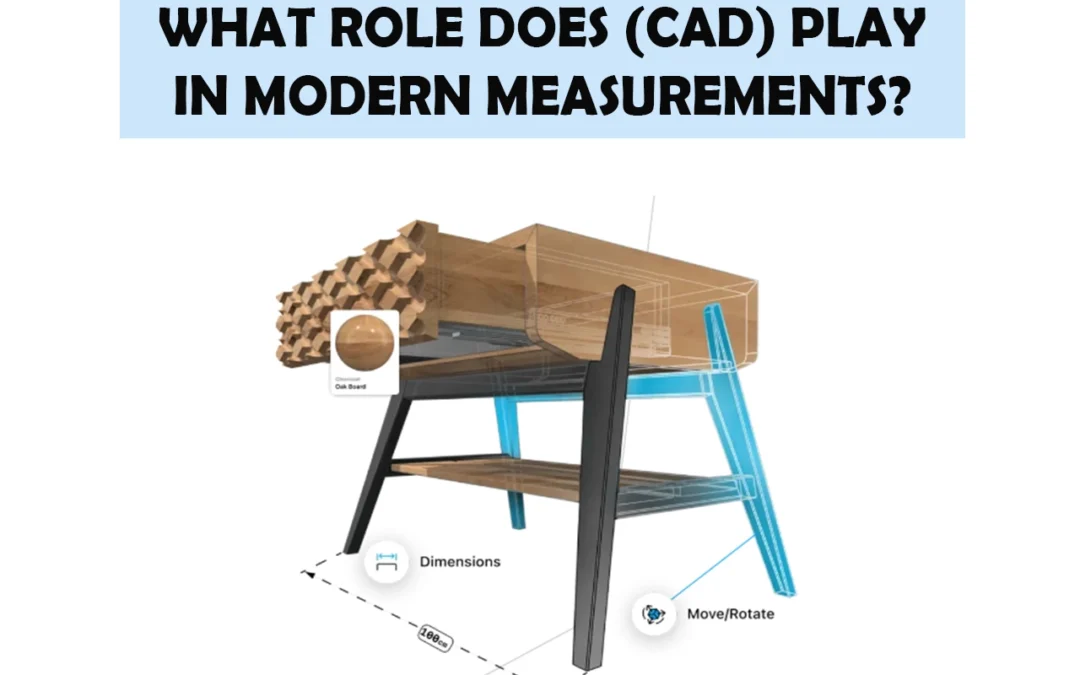

Are you a woodworker looking to get the most out of your craft? Consider using computer-aided design (CAD) technology. CAD is like a digital toolbox, allowing you to measure with precision and accuracy, making tasks much easier than if done by hand.

With CAD, you can create detailed plans for any type of woodworking project. This article will explore the role that CAD plays in modern woodworking measurements, from its advantages to its challenges and future applications.

Learn how CAD has revolutionized woodworking measurements and the many benefits it offers, so you can maximize your projects with ease!

Key Takeaways

- CAD technology revolutionizes woodworking measurements, making it easier and faster than ever before.

- CAD eliminates manual labor and allows woodworkers to focus on design and craftsmanship.

- CAD allows for accurate measurements and a wider range of design possibilities.

- CAD saves time and money by eliminating errors and wasted materials.

Overview of CAD Technology

CAD technology has revolutionized the way woodworkers take measurements, making it easier and faster than ever before! CAD software provides precision cutting by allowing for intricate shapes to be cut with accuracy. It also enables automation of the cutting process, freeing up time for more creative tasks. The use of CAD eliminates most of the manual labor that comes with traditional woodworking measurement techniques. This allows woodworkers to focus on more important aspects such as design and craftsmanship.

The use of CAD in woodworking not only allows for accurate measurements but also allows for a much wider range of possibilities when it comes to designing furniture. This is due to its versatility, allowing users to easily modify designs or add new features without having to redo the entire process from scratch. Additionally, CAD can be used to simulate how a finished product will look before any physical work takes place. This helps ensure that the finished product is exactly what was intended and cuts down on wasted materials or time spent fixing mistakes after production has begun.

Using computer-aided design in modern woodworking makes measuring and creating furniture simple and efficient. With its precision cutting capabilities and ability to automate processes, CAD enables both beginners and experts alike to quickly create quality pieces with ease. By eliminating errors caused by manual labor, using CAD ensures that projects are completed accurately while saving time and money along the way – all important factors when making furniture!

As we move further into this digital age, CAD technology continues to play an increasingly important role in modern woodworking measurements – offering convenience like never before seen in this industry.

Advantages of Using CAD

You’ll love the advantages that CAD brings to woodworking measurements – accuracy, precision, and a whole lot more! Thanks to computer-aided design technology, accuracy improvement is made possible when measuring wood.

With CAD systems, there’s no need for guesswork as the measurements are calculated automatically with high precision. This eliminates errors caused by human oversight that could lead to inaccuracies in measurements. Moreover, using CAD helps save time since it’s faster than manual processes as all of the calculations are done quickly by computers or software programs.

Additionally, compared with traditional methods of measurement like rulers or tape measures, CAD allows for greater flexibility in designing pieces of wood furniture. The ability to modify designs on-screen makes it easier for woodworkers to make changes if needed—without having to start from scratch. Plus, new features and capabilities can be added over time with regular updates and upgrades, which further enhance its value in modern woodworking measurements.

CAD also offers many other useful benefits such as improved visualization capabilities during planning stages and simulation tools that allow you to test out different scenarios before fabricating a piece of furniture. All these advantages make computer-aided design an invaluable asset for any modern woodworker looking for accuracy and efficiency in their workflows.

Moving on to measuring wood with CAD can improve your productivity while delivering top-notch results every time!

Measuring Wood with CAD

You can measure wood with CAD by using digital protractors, digital calipers, and 3D modeling software.

Digital protractors are used to accurately measure angles and curves in a piece of wood.

Digital calipers can be used to precisely measure the thickness and depth of the wood.

Finally, 3D modeling software can be used to create detailed designs that are easy to follow when cutting pieces of wood.

With CAD, you’ll have highly accurate measurements for any project you need to do with wood!

Use of Digital Protractors

Modern woodworking measurements rely heavily on the use of digital protractors as they enable precise, accurate readings and can help save time. Digital surveying and laser scanning ensure that every angle is measured accurately, quickly, and with repeatability – allowing woodworkers to work with confidence in their measurements.

Protractors measure angles with accuracy up to 0.1 degrees.

Laser scanning technology maps out complex shapes in minutes.

Digital surveying can measure lengths up to 1/1000th of an inch.

Digital protractors provide a level of precision that was previously impossible for woodworkers, making it easier to create intricate pieces while staying within design tolerances. This level of accuracy allows for more efficient production times and greater creativity when creating woodworking projects.

Transitions into the next step in modern woodworking measurements are seamless due to the accuracy offered by digital protractors.

Use of Digital Calipers

Digital calipers make precise measurements a breeze, allowing you to craft your woodworking projects with confidence. They provide accuracy assessment and dimensional analysis to ensure that each part of the project is exact and perfect.

Calipers are incredibly useful when measuring the thickness of materials, as well as internal and external diameters. These tools are highly accurate and can measure in millimeters or inches, so you can work confidently knowing that all your calculations are correct.

Additionally, digital calipers allow for quick and easy readouts which save time during complex projects. Using these tools can give you a competitive edge by providing accurate measurements in far less time than manual methods. With digital calipers, you can take on even the most challenging woodworking tasks with ease and precision.

As such, they play an essential role in modern woodworking measurements for accuracy assessment and dimensional analysis.

Now let’s move on to how 3D modeling software adds to this process.

Use of 3D Modeling Software

3D modeling software revolutionizes woodworking, allowing you to craft complex designs with perfect precision in less time than ever before. With the help of 3D printing and laser cutting technology, CAD programs enable accurate measurements to be taken quickly and precisely.

This means that intricate details can be calculated more efficiently, thereby saving both time and money when it comes to woodworking projects. Furthermore, CAD allows for the visualization of ideas on a computer screen before implementation so any potential errors or mistakes can be identified and corrected before they become costly problems.

As such, CAD plays an invaluable role in modern woodworking measurements, providing users with an efficient way to design projects with confidence. Consequently, this provides an excellent transition into discussing the different types of woodworking measurements available today.

Types of Woodworking Measurements

Using CAD, woodworkers can quickly and accurately measure a variety of dimensions for their projects. Woodworking measurements may involve determining the width or height of a piece or analyzing the grain pattern of a particular cut. CAD allows woodworkers to take precise measurements within seconds, saving them significant amounts of time and effort.

It also enables them to take measurements from difficult-to-access areas where traditional methods are not practical. Furthermore, CAD can be used to determine the optimal cutting techniques for various types of wood and different grain patterns. This helps woodworkers achieve consistent results that meet high standards of craftsmanship.

By utilizing computer-aided design software, measuring complex shapes and intricate details is now easier than ever before. In addition, CAD helps in verifying whether components fit together properly before any cuts are made. As such, it has revolutionized how woodworking measurements are taken and used in modern carpentry projects.

How CAD Has Revolutionized Woodworking Measurements

You can now take precise measurements quickly and easily with the help of modern computer-aided design, revolutionizing woodworking measurement processes. CAD allows for:

- Precision machining of complex shapes and curves

- Automated cutting to reduce errors caused by manual measurements

- The ability to measure large objects without needing a physical ruler or tape measure

- Increased accuracy in measurements, down to fractions of an inch

- Quicker turnaround times for measuring tasks

These advancements have made it easier for woodworkers to achieve exact results when making furniture, cabinetry, or any other project that requires exact measurements. From milling projects with intricate shapes and angles, to accurately cutting boards at specific lengths, CAD has opened up a whole new world of possibilities for precise woodworking measurement.

Its uses are not limited just to measuring — CAD is also used in 3D modeling and prototyping pieces before they go into production.

CAD has become indispensable in today’s era of rapid prototyping and mass customization; it enables woodworkers to produce parts faster than ever before while keeping them accurate and consistent from piece to piece. With its help, woodworking projects can be finished more quickly and efficiently than ever before — all while maintaining tight tolerances on dimensions that would otherwise be difficult or impossible to achieve without this powerful technology.

As such, CAD has become an essential tool in modern woodworking measurement processes.

Common Uses of CAD in Woodworking

Thanks to CAD, woodworking measurements have been revolutionized. Nowadays, automated measurements and laser scanning can be used to accurately measure the size and shape of large wooden objects, as well as the details of smaller ones. This provides a more efficient and accurate way to take precise measurements than manual methods allow.

CAD can be used for a variety of purposes in woodworking. It can be used to create plans for furniture pieces or structures and to create cut lists for cutting out parts accurately on saws or CNC machines. It also allows designers to rapidly create 3D models that can be used for visualizing the final product before it is built. CAD programs can also generate drawings with all necessary dimensions included so that construction workers know exactly how an object should look.

Woodworkers are increasingly using CAD software to simulate complex joinery operations such as dovetailing joints or mortise-and-tenon joints and test their strength before actually building them. This helps save time by allowing them to identify potential problems before they start building the piece, which could result in costly mistakes if done manually. Additionally, CAD software makes it easier to make changes quickly during design iterations without having to start over from scratch every time something needs adjusting.

With these capabilities at hand, woodworkers now have a powerful tool at their disposal that allows them greater control over their projects’ accuracy while saving time and money throughout the process. The benefits of using CAD in woodworking are clear: faster production cycles with fewer errors resulting in higher quality products overall – a win-win situation for everyone involved!

With precision measurement taken care of by automated systems, it’s no wonder why many professionals rely on this technology day after day when crafting wooden objects. Moving forward into the next section, we’ll explore some additional benefits of using CAD in woodworking today.

Benefits of Using CAD in Woodworking

Benefiting from modern technology, you can take precise measurements and plan complex joinery operations quickly with CAD in woodworking. By leveraging its impressive capabilities, users can achieve accuracy improvement and design optimization.

- CAD allows for detailed drawings to be made with a high degree of precision.

- It helps save time by streamlining the design process and reducing the need for manual craftsmanship.

- The software enables multidimensional views of the project, which facilitates visualizing how objects interact in three-dimensional space.

CAD also provides an efficient way to create models of physical objects or virtual prototypes for testing before implementing them in real-life applications. This helps identify possible issues early on and reduces costs due to material waste or errors. Additionally, CAD is extremely helpful when creating complex assemblies, as it makes it easier to keep track of components used in a project and ensure compatibility between different parts.

Overall, this tool offers great advantages that make woodworking measurements much more accurate and reliable than ever before while speeding up production times significantly. As such, it has become an essential part of modern carpentry practices today.

Transitioning into the challenges posed by CAD, however, requires further exploration…

Challenges of Using CAD in Woodworking

Now that you have an understanding of the benefits of using CAD in woodworking, let’s look at the challenges.

Although CAD can be extremely helpful, it does come with some drawbacks. For starters, there is a tradeoff between accuracy and workflow optimization. As more time is taken to measure and adjust dimensions for accuracy, less time is available for completing projects promptly.

Additionally, CAD takes experience to operate correctly, as well as knowledge of tools like SketchUp or other software programs. Furthermore, most woodworking plans require multiple measurements and angles which could take longer when measured by hand than with proper computer-aided design techniques.

In addition to these points, converting existing drawings into digital format can also be difficult and costly if done incorrectly or without the right technology.

CAD may not always be the best option when it comes to woodworking measurements; however, its importance in modern-day carpentry cannot be denied. It has made many aspects of this craft much easier by streamlining processes and providing accurate results quickly – something that was not always achievable before its introduction into the trade.

Moving forward into the future of CAD in woodworking will open up new possibilities and opportunities for carpenters around the world who are looking to perfect their craft – but only if used correctly and efficiently.

With that being said, let’s take a look at what lies ahead…

The Future of CAD in Woodworking

You’re in luck – the future of CAD in woodworking is looking bright! The use of computer-aided design (CAD) for modern woodworking presents many advantages.

CAD enables woodworkers to create detailed designs quickly and cost-effectively, making it cost-effective.

It eliminates time-consuming manual calculations, allowing workers to focus on other tasks, saving time.

CAD ensures precision measurements with minimal errors or inconsistencies across projects, ensuring accuracy.

The use of CAD has been steadily growing over the years, as more and more professionals recognize its benefits. As technology advances, so does the potential for greater accuracy and cost savings when creating plans using this software.

Advancements in automation are making it easier to integrate automated processes into existing workflows, potentially leading to increased efficiency and further cost savings in the long run.

In summary, CAD offers numerous advantages that are attractive to woodworkers at all skill levels and experience levels alike. From cost savings and time savings to accuracy and automation capabilities, there’s no doubt that this technology will continue to play an important role in modern woodworking measurements for years to come!

With these considerations in mind, let’s now take a look at the summary of the benefits of using CAD in woodworking.

Summary of Benefits of CAD in Woodworking

Woodworking’s now much swifter with CAD, providing cost savings and accuracy galore! Computer-aided design (CAD) has revolutionized the modern woodworking industry by providing an efficient and precise means of measuring wood.

With CAD, workers can quickly create detailed measurements that meet exacting specifications with less time and effort than ever before. The accuracy improvement from using CAD is invaluable for woodworkers in avoiding costly mistakes. Additionally, since fewer resources are needed for projects with CAD, it also saves time and money on labor costs.

Using CAD also allows woodworkers to maintain consistency across their projects, making sure each piece is identical to the next. Furthermore, shared designs can be easily transferred between different parties involved in a project, streamlining communications as well as saving on production costs. This enhanced communication efficiency leads to better collaboration between teams, resulting in higher-quality products being produced faster than ever before.

Overall, computer-aided design (CAD) plays a pivotal role in modern woodworking measurements. It allows for greater speed of production while maintaining accuracy and cost savings over traditional methods of measurement. It has become an essential tool for any successful woodworker looking to keep up with today’s competitive markets. Its use ensures that all pieces will meet the exact specifications required, resulting in superior quality products delivered faster than ever before!

Conclusion

You’ve just seen how computer-aided design (CAD) has revolutionized the way woodworking measurements are taken. CAD has made it possible for woodworkers to produce high-quality products quickly and efficiently. It has been found to reduce time spent on measurements by up to 80%. With these impressive benefits in mind, it’s easy to see why CAD is essential to modern woodworking.

Frequently Asked Questions

What is the difference between CAD and other woodworking measurement tools?

CAD offers accuracy advantages and time savings over manual woodworking measurement tools. It is more precise, allowing for detailed designs that can be reproduced quickly and efficiently.

What type of hardware and software is needed to use CAD?

You need a computer with at least 8GB of RAM, an up-to-date operating system, and specialized CAD software to use CAD. The learning curve for this technology is steep but the time investment can be well worth it; in fact, it’s estimated that CAD increases efficiency by over 50%.

What is the cost of using CAD for woodworking measurements?

Using CAD for woodworking measurements is cost-effective when compared to traditional methods due to its accuracy and time savings. Consider the costs of hardware and software, as well as training and maintenance, to maximize accuracy comparisons and time savings.

Are there any safety considerations for using CAD in woodworking?

When using CAD for woodworking, proper setup and accuracy checks are essential. For example, imagine a carpenter measuring 5 times to ensure precision before starting the job. Similarly, CAD requires careful preparation and regular testing to guarantee safety. With the correct setup and double-checking of accuracy, you can confidently use CAD in woodworking.

Are there any limitations to using CAD for woodworking measurements?

When using CAD for woodworking measurements, accuracy implications and labor costs may arise. Accuracy can be affected by user errors or technical difficulties while increased labor costs may result from the time taken to set up and learn the system.