Have you ever walked into a woodworking shop and felt overwhelmed by the variety of tools available? You may have wondered what each tool is used for and why they are necessary.

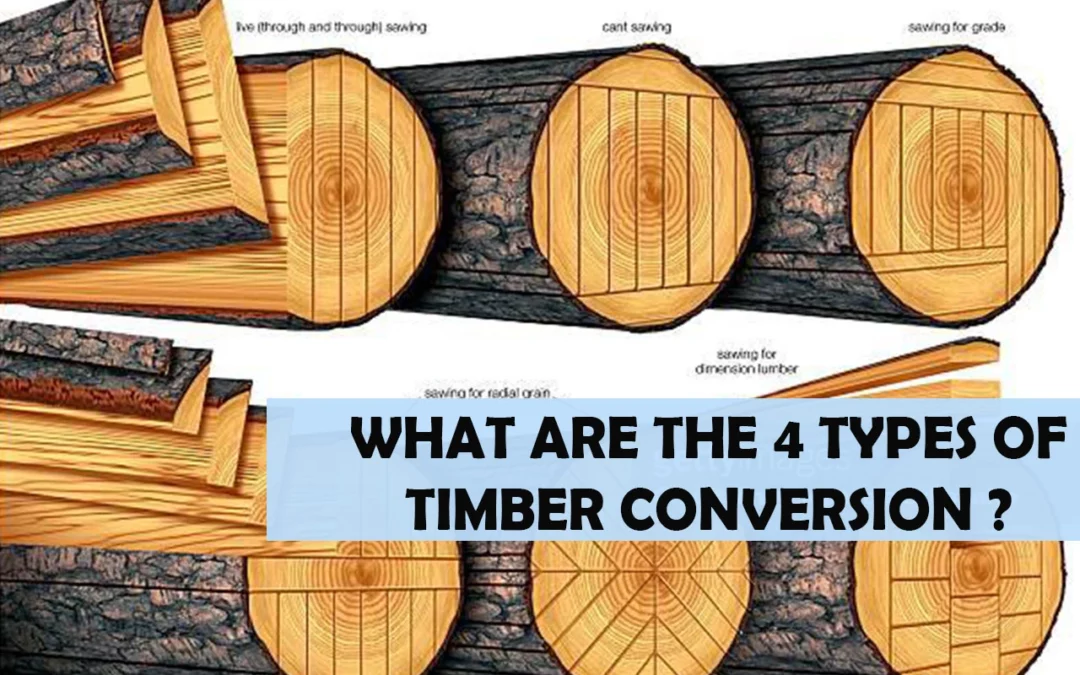

When it comes to timber conversion, there are four main types that must be mastered in order to create beautiful pieces of furniture or art. Coincidentally, these four types – joining, shaping, finishing, and assembly – all play an important role in transforming basic timbers into something extraordinary.

Join us as we explore each type of timber conversion in detail to understand how they work together to create stunning woodworking projects.

Key Takeaways

- Joining is an important aspect of timber conversion in woodworking, involving aligning and securing wood pieces using various techniques such as sanding, finishing, and fasteners.

- Shaping timber involves processes like sanding, routing, planing, and mortising, which help to achieve the desired shape and texture.

- Finishing plays a crucial role in woodworking, as it includes staining, varnishing, and paying attention to detail to enhance the appearance and protect the finished pieces.

- Assembly methods like glue-ups, biscuit joining, and dowel joining are commonly used to join timber pieces together, providing strength and stability to the final product.

Joining

Joining two pieces of wood together can be like an interlocking puzzle, creating a snug fit that’ll last. To achieve this kind of joinery, you must make sure the two pieces are properly aligned and secured.

This is where sanding techniques and finishing tips come into play. Sanding down the edges can help create a seamless connection between the two pieces. Finishing with a sealant or varnish will ensure your work won’t wear away quickly due to weathering or general wear and tear.

Additionally, using fasteners such as nails or screws will provide an extra level of stability for heavier objects or structures.

Achieving proper joinery requires careful attention to detail and patience in order to get it right, but once done correctly, it provides a strong bond between two separate parts that will stand up to the test of time.

With the right supplies and tools, joining timber is relatively easy as long as you take your time to get it right. And with that in mind, let’s move on to shaping timber for your next woodworking project!

Shaping

Shaping wood can be a creative and enjoyable experience; you’re turning a raw material into something beautiful that’s both functional and aesthetically pleasing. Here are just some of the shaping techniques you may use when working with wood:

- Sanding: This is one of the most basic shaping techniques, used to smooth surfaces or remove small amounts of material. It can also be used to create an interesting texture on the surface of your piece.

- Routing: This technique involves using a router to cut away material from the edges of your workpiece in order to shape it.

- Planing: This is another common technique used for shaping wood, which involves running a hand plane over the surface of your workpiece in order to make it level and even.

- Mortising: Mortising is a technique used to create precise holes in the wood so that it can fit around other components like dowels or pegs. This technique requires careful measurements and precision in order for it to be done correctly.

These four techniques are essential for any woodworker looking to create unique pieces from their raw materials. With practice, patience, and skillful execution, these methods will enable you to craft beautiful pieces that will last for years.

To complete your projects with finesse, you’ll need more than just these basic techniques – there’s still finishing to consider!

Finishing

Once you’ve shaped and routed your piece, the next step is to finish it off with a beautiful finish!

Finishing is the last step in timber conversion and can involve staining, varnishing, or other techniques. It’s important to pay attention to detail during this process as any errors here will be visible once the piece is complete.

It’s critical that you use the right tools and products for finishing. If you don’t have experience with woodworking, it may be best to hire an expert who knows what types of stain and varnish are appropriate for different types of wood. You also need to consider how long each coat should take to dry before applying another one.

When staining, make sure not to rush – apply it slowly and evenly so that all areas are covered equally. Apply a thin layer of varnish afterward for protection against spills or scratches; this will help keep your project looking its best over time. With both staining and varnishing techniques, always use even brush strokes when applying the product onto the surface for a more professional result.

After these steps are completed correctly, your project should look great! Achieving a perfect finish takes patience and practice, but if done correctly, it can really bring out the beauty in any piece of timber conversion artwork.

Properly caring for finished pieces can also help them last longer – regular cleaning with a damp cloth will keep dust away from surfaces while maintaining their appearance.

Now that your timber has been transformed into something special, it’s time to move on to assembly!

Assembly

Assembly is an important part of woodworking that involves joining pieces of timber together. The three main methods for doing this are glue-ups, biscuit joining, and dowel joining.

Glue-ups involve using adhesives to bind the pieces of timber together. Biscuit joining uses a small wooden biscuit to help keep the pieces aligned, and dowel joining uses cylindrical pegs to hold the pieces in place.

All three techniques can be used effectively when constructing furniture or other woodworking projects.

Glue-ups

Gluing is an integral part of timber conversion in woodworking, allowing for the construction of bigger and more complex projects. Glue-ups involve laminating multiple pieces together with either pocket hole joining or biscuit joining. This process involves applying adhesive to each piece and clamping them together until the glue has dried.

The strength of this joint depends on the type of glue used, but it can also be reinforced with screws or nails if desired. Glue-ups are ideal for making large panels, such as tabletops or cabinet doors, as well as creating intricate carvings from a single piece of wood.

By combining different types of gluing techniques, woodworkers can create unique and beautiful items that would otherwise be impossible to make. With its versatile nature, glue-ups are essential for any timber conversion project in woodworking.

Biscuit Joining

Moving on from glue-ups, biscuit joining is another popular type of timber conversion in woodworking. This technique involves cutting a rebated or mortised hole into the two pieces of wood and then inserting a thin, oval-shaped biscuit into the holes. The biscuit swells when it comes into contact with water-based glue, creating an incredibly strong bond between the two pieces.

The biscuit also adds strength to joints by filling in small gaps that may have been caused during machining. This makes it perfect for use on furniture or other items where precise fitting isn’t possible. Biscuit joining is an incredibly useful tool for any woodworker looking to create strong connections while maintaining accuracy and aesthetics.

Now that you know about biscuit joining, let’s take a look at dowel joining for even more options in timber conversion!

Dowel Joining

Dowel joining is an easy way to create a strong and lasting bond between two pieces of wood without needing to use glue. It’s a simple, but effective, routing technique that involves using dowels and accurately placing them in pre-drilled holes on the wood for maximum connection strength.

Here are some of its benefits:

- Dowels provide more surface area for adhesion than nails or screws alone.

- Dowel joints are stronger and last longer than most other types of joinery.

- Doweling is faster than traditional mortise-and-tenon joinery techniques.

- It’s relatively easy to make accurate dowel placements with the right tools and practice.

With these advantages in mind, it’s clear why dowel joining is one of the most popular methods used in woodworking for creating sturdy connections between two boards.

Transitioning into the next step of cutting allows you to begin shaping your project to its desired final form.

Cutting

Cutting is a key part of woodworking; for example, you could cut a piece of timber to make a new table top. There are several types of cutting used in woodworking, including planing, sanding, routing, and pocketing.

Planing is the process of shaving off thin layers from the surface of timber using a plane. Sanding involves using abrasive materials such as sandpaper to smooth the surfaces of timbers. Routing is an advanced technique that uses tools with rotating blades to make precise cuts into timber and create decorative designs or patterns. Pocketing involves using routers equipped with specialized bits to create holes or pockets in timber pieces.

Cutting can be done manually or with machines depending on what type of cut you need and how precise it needs to be. Manual cutting requires more skill but allows for greater control over the final results, while machine cutting yields faster results but may not always result in perfectly even cuts. Cutting also requires that you use sharp tools to ensure clean cuts that won’t leave splinters behind when handling the finished product.

No matter what type of cut you’re making, safety should always be your first priority when working with timber and other woodworking materials. Make sure all power tools are switched off before adjusting them and wear protective gear such as goggles and gloves when necessary. Taking these precautions will help ensure that your project turns out successfully without any accidents along the way!

Conclusion

In woodworking, there are four main types of timber conversion: joining, shaping, finishing, and assembly. All require a high level of precision and skill to create beautiful pieces of furniture that stand the test of time.

Every step is like a puzzle piece that must fit perfectly together for the final product to be successful. With dedication and practice, you can master these skills and become an expert in timber conversions.

Your work will be as strong as a rock and look like it was crafted by the gods themselves!

Frequently Asked Questions

What is the best type of saw to use for timber conversion?

When selecting a saw for timber conversion in woodworking, it is important to consider saw blade selection and woodworking techniques. An ideal saw should have an adjustable blade depth, an ergonomic handle, and a powerful motor to ensure precise cuts.

What is the most cost-effective method of timber conversion?

Considering timber prices and wood sources, the most cost-effective method of timber conversion is to use a band saw. With its narrow blades, band saws are more efficient than other types of saws and can be used for curved cuts as well as straight cuts.

What safety measures should be taken when working with timber?

Take the necessary precautions when working with timber. Use proper handling techniques and protective gear to ensure your safety. Ensure you have the right tools for the job, and use them correctly. Timber protection is key in avoiding accidents or damage to both yourself and the timber.

Are there any environmental considerations when converting timber?

Yes, there are environmental considerations when converting timber. Minimizing waste and using sustainable practices can help ensure the process is eco-friendly. This includes disposing of scrap wood properly and utilizing renewable materials whenever possible.

Is there a difference between timber conversion and woodworking?

Yes, there is a difference between timber conversion and woodworking. Timber conversion involves surface preparation and tool selection to change the form of the timber, while woodworking focuses on crafting furniture or other items from raw materials.