A Beginner’s Guide To Using Routers Safely In Woodworking

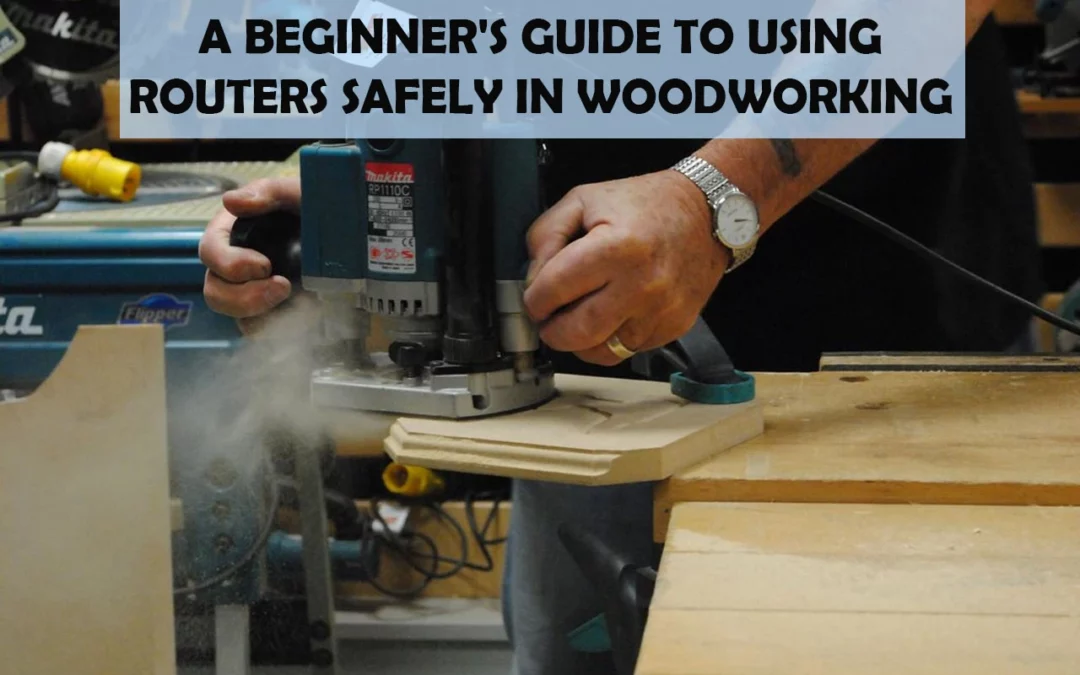

Are you a beginner woodworker looking to master the art of using routers? If so, you’re in the right place!

Take it from Joe, an amateur woodworker who was once scared of using routers but eventually became confident enough to take on any project. After much trial and error, he learned how to use routers safely and efficiently – something every woodworker should strive for.

In this article, we’ll cover safety equipment, setting up your router table, choosing the right router bit and more. By learning these techniques and following some important safety tips along the way, you’ll be well on your way to becoming a successful router user.

So don’t worry – just read on and soon you’ll be routing like a pro!

Key Takeaways

- Importance of practicing good technique and maintaining proper posture in woodworking

- Regular maintenance of router for woodworking safety

- Inspecting the bit before routing wood

- Using personal protective equipment when operating a router

Safety Equipment

When using a router, it’s important to wear safety glasses and gloves to protect your eyes and hands. It is also essential to wear a dust mask as routers can create a lot of dust which can be hazardous if inhaled. Make sure you follow all instructions given by the manufacturer regarding safety equipment when using your router.

Before starting any routing project, set up your workspace carefully. This includes ensuring that the area around the router is well-lit and free from obstructions or debris. Place the router on a stable surface away from edges that could cause the bit to catch or break off during use.

Make sure there is enough space for all tools and materials needed for your project before proceeding with routing operations.

Pay close attention to detail while setting up your router table so that you don’t miss any potential hazards before beginning work on your woodworking project. Take into consideration any additional accessories you may need such as an adjustable fence, feather boards, and other necessary attachments so that you are working safely with the right setup in place.

Routers are powerful tools used in woodworking projects, but they must be used safely at all times in order to prevent injuries or accidents from happening while working with them. Taking time to prepare properly with proper safety equipment along with setting up your router table correctly will help ensure safe operation when using this tool. With these steps taken care of, you’re ready to start creating beautiful works of art out of wood!

Set Up Your Router Table

You’re ready to set up your router table so you can get started woodworking!I

nstalling the router is the first step and it needs to be done securely.

Next, you’ll need to adjust the table height for each project.

Finally, make sure that you mount the fence properly for optimal accuracy when routing.

With these steps complete, you’re all set to start exploring new projects with your brand-new router table!

Installing the Router

Before starting to use a router, it’s important to properly install it – but how? Installing the tools of your router correctly can be a daunting task. To ensure you do it safely and correctly, here are some tips:

- Selecting the right bit: It’s essential to choose the correct bit for your router project. Doing so will ensure that your project runs smoothly and without any hiccups.

- Attaching the bits securely: Make sure that all bits are firmly attached and secure before using them. This is especially important when working with more delicate materials or projects.

- Adjusting the depth stop: The depth stop should be adjusted according to what type of material you’re using as this helps determine how deep the cut goes into it.

- Connecting power source: Make sure that all wires are connected properly and securely by following manufacturer guidelines for installation. Failing to do so could result in an electrical accident!

- Inserting collet nut & lock nut: Properly installing these pieces ensures that everything remains stable during operation, which reduces the chances of any accidents occurring while using a router table.

Once you’ve installed your router correctly, you can move on to adjusting the table height for optimal performance.

Adjusting the Table Height

To ensure your router works optimally, you need to adjust the table height carefully and precisely. Leveling surfaces is key for achieving uniform cuts, so use a level to check that each surface of the table is parallel with the ground. Then, adjust the height of the surface accordingly. Make sure to use a dust collection system to keep sawdust from entering your lungs as you work. Be sure to tighten all screws securely before moving on to mounting the fence.

Once everything is set up correctly, you’ll be ready to begin routing!

Mounting the Fence

Now that your table is level, you’re ready to mount the fence. Secure it firmly into place with screws and bolts so you can begin routing with confidence.

To ensure proper alignment, make sure the fence is mounted square to the tabletop and parallel to the bit depth. Check for any gaps between the fence and the bit, adjusting where necessary until they are perfectly flush.

Once everything is secure, you can move on to choosing the right router bit for your project.

Choosing the Right Router Bit

Finding the perfect router bit for your project can be tricky, but with a few key tips, you can be sure to choose the best one!

Selecting router bits is an important step in woodworking; it’ll determine the quality of your finished product. There are several different types of router bits, and each type has its advantages and disadvantages. For example, spiral-fluted router bits are great for quickly cutting through softwoods, while straight-fluted router bits are better suited for hardwoods. Additionally, some router bits feature carbide edges that stay sharp longer than steel blades.

Before selecting a router bit, it’s important to consider what kind of material you’ll be cutting as well as the desired finish. If you’re working with softer woods such as pine or cedar, then a spiral-fluted bit might work best. For harder woods like oak or walnut, a straight flute will provide more control and accuracy when making intricate cuts or shapes. When it comes to achieving a smooth finish on your project surface, carbide-tipped bits tend to produce better results than steel blades.

No matter which bit you choose for your project, always make sure that it’s properly secured in the collet before using it. Additionally, regularly check to make sure that all screws and bolts are tight before using the machine; that’ll help ensure that everything works correctly and safely throughout your woodworking session.

With these simple tips in mind, you’ll have no problem finding the right router bit for any job!

Router Safety Tips

When working with a router, safety is paramount. To ensure a safe woodworking experience, it’s important to secure the workpiece firmly to your workbench. Use proper technique when operating the router and avoid overreaching. Taking these precautions will help you stay safe while using this powerful tool.

Secure the Workpiece

Securely affixing your workpiece is essential for router safety. To do so, you should always use securing hardware such as clamps or a jig to hold the piece in place. This will allow you to be more precise while routing and ensure your workpiece stays in its correct position throughout the routing process.

Additionally, using dust control devices like a vacuum can help to keep the area clean and prevent debris from getting into the workspace, which can create hazards.

Lastly, ensure that all securing hardware is firmly tightened and double-check before each pass of the router bit. By taking these precautions, you’ll be able to confidently use a router with greater accuracy and efficiency while also keeping yourself safe – helping you get great results every time.

Use Proper Technique

Now that you’ve got your workpiece secured, it’s important to use proper technique while routing. To avoid injury, make sure you’re standing in a comfortable position with good posture and holding the router firmly. Maintain a steady speed and pay attention to where the bit is at all times.

Additionally, be sure to keep your hands away from the bit and never try to reach over it. By following these tips and ensuring proper posture and safe speeds, you can get the job done safely every time – without sacrificing quality!

Now let’s move on and discuss how to avoid overreaching when using a router.

Avoid Over-Reaching

Be careful not to overextend yourself when routing – it’s easy to become swept up in the rhythm of the project and forget safety first! To avoid overreaching, make sure to maintain proper posture while using your router. Keep your arms close to your body with elbows bent and stand with a wide stance for balance.

Additionally, use guards on the router whenever possible to prevent any accidents or injuries. While this may seem tedious at first, guards will help you stay safe as you work. An important reminder when routing is that safety comes first – take breaks if needed and always practice good techniques such as maintaining proper posture and using guards.

With these tips in mind, you’ll be able to enjoy woodworking without any unnecessary risks or dangers.

Maintaining Your Router

Performing regular maintenance on your router is an important part of woodworking safety. To keep your router working properly, you should inspect the bits, clean the router table, and sharpen the bits regularly.

Doing so will ensure that you get a smooth cut every time and prevent any potential hazards while using the router.

Inspect the Bit

Before you begin routing your wood, take the time to examine the bit carefully to ensure it’s in good condition. Inspecting tools such as router bits should be part of your routine before beginning any woodworking project.

Selecting a sharp, undamaged bit is essential for achieving clean and accurate cuts. If you find that the cutting edges are dulled or chipped, replace the bit immediately with one in better condition. Likewise, be sure to check that there are no cracks or other damage along its length.

Properly maintained router bits will help create precise results while minimizing tear-out and chipping on both sides of the cut line. By taking these precautions beforehand, you’ll have a much smoother routing experience overall!

With your bit in top shape, you’re now ready to move on to cleaning the router table surface.

Clean the Router Table

Before starting any routing project, it’s important to ensure your router table surface is clean and free from debris. Make sure you use a dust collection system, as well as blade guards, to prevent the accumulation of sawdust.

To begin cleaning, use a vacuum hose or brush attachment to remove excess dust and particles from the tabletop. After that, wipe down the entire surface using a soft cloth dampened with mineral spirits or denatured alcohol. This will help remove any sticky residue left behind by wood glue or finish.

Finally, check for any nicks or dings in the tabletop that could interfere with alignment when setting up your router bit. Once everything is clean and smooth, you’re ready to move on to sharpening your bits and get ready for routing!

Sharpen the Bits

Sharpening router bits is a crucial step to get the most out of your routing projects, so let’s get started! It’s important to select the right type of bit for your project and understand the sharpening techniques you’ll need.

For best results, use a grinding wheel or an oil stone for larger bits, and use diamond-coated hones or sandpaper on smaller ones. Make sure you sharpen both cutting edges at the same angle and that they match each other perfectly.

Also, be mindful of maintaining a consistent tip angle when sharpening. This will help ensure better control over cuts and reduce tear-out while routing.

With these tips in mind, you’ll be ready to move on to final thoughts about using routers safely in woodworking!

Final Thoughts

Now that you have a better understanding of how to safely use routers in woodworking, make sure to regularly check your router bits for sharpness and wear. Taking the time to choose the right material and practice proper technique will help you avoid any damages or accidents while routing.

Be sure to inspect each bit before, during, and after use for any signs of wear or damage. If you find any, replace them immediately with a new one. Additionally, always remember to use personal protective equipment when operating a router – like eye protection, dust masks, earplugs/muffs – as these tools generate strong vibrations which can be harmful if not handled correctly.

Cleanliness is also key when using routers in woodworking projects. Make sure all the components are clean of dirt and debris before use and never leave your workspace messy when done working. This will help prolong the life of your tools and ensure they’re always ready for action whenever needed.

Finally, it is important to properly store your router bits – whether in a toolbox or carrying case – so that they stay safe from harm and moisture while not in use.

Taking these safety precautions into account will go a long way toward ensuring successful woodworking projects involving routers each time you put them into action. With this knowledge under your belt, you can move forward with confidence as you begin creating more intricate pieces from now on!

To further enhance your experience with routers, be sure to check out our helpful resources section below for additional tips and tricks.

Resources

Gain the knowledge you need to confidently create intricate pieces with routers by exploring our helpful resources section below.

If you’re new to using routers, start by learning the basics and browsing through buying guides that explain the different types of router bits and other features available. You’ll also find step-by-step tutorials on how to use a router safely and correctly.

For more experienced users, there are advanced tutorials for complicated projects as well as troubleshooting guides for when things go wrong. Additionally, many websites offer video demonstrations of woodworking projects that show exactly how they should be done from start to finish.

When in doubt or feeling stuck, don’t hesitate to contact an expert at your local home improvement store or online forum who can help guide you through any difficulties you might be facing.

With these valuable resources at your disposal, you’ll be able to make beautiful creations with a router without having to worry about safety issues.

Conclusion

In conclusion, woodworking with routers is a craft that takes skill, patience, and knowledge. With the right equipment, safety tips, and maintenance, you’ll be ready to create beautiful works of art from any piece of wood.

As you carve your way through each project, take pride in knowing that each stroke of your router creates something unique and special—a timeless symbol of your creativity and hard work.

Frequently Asked Questions

What is the difference between a fixed base and a plunge router?

When using a router, the difference between a fixed base and a plunge router is that with a fixed base, you have more control due to its stationary position while plunging involves lowering the bit into the material. Securely mounting your router ensures safe use and proper care will keep it working for years.

What is the best type of router to use for beginner woodworkers?

For a beginner woodworker, the best router is one with a fixed base. Look for a model that offers ease of use and maintenance. Strike the right balance between power and control – don’t bite off more than you can chew! With proper care, your router will be your trusty sidekick for years to come.

How do you adjust the router bit depth?

Adjust the router bit depth by setting limits on the depth of cut and choosing speeds that are appropriate for the task. Follow safety rules to ensure a successful outcome.

What is the best way to sharpen a router bit?

Do you want to keep your router bit sharp for precision woodworking? Sharpening techniques and regular router maintenance are key. Try using a diamond file to sharpen the edges of your bit, or use an automated sharpening machine for convenience. Keep your bits in top condition and you’ll be ready for any project!

Is it necessary to use a dust collection system when using a router?

Yes, using a dust containment system is essential for safety protocols when using a router. It helps keep the work area clean and prevents airborne particles from becoming hazardous.