From jigsaws to table saws, woodworking saws are powerful and precise tools for cutting through a variety of materials. But did you know they are designed with safety features like finger detection technology?

This article will explore how woodworking saws detect fingers and the advantages of pressure and optical sensors. You’ll also learn some useful safety tips to keep your fingers safe when using these tools.

By understanding the capabilities of modern woodworking saws, we can use them more confidently with greater peace of mind. Let’s dive into the fascinating world of woodworking power tools!

Key Takeaways

- Woodworking saws use finger detection technology for safety.

- Pressure and optical sensors are used to detect fingers near the blade.

- Sensors can shut off the saw if finger contact is detected.

- Proper maintenance and following safety protocols are crucial when using woodworking saws.

Overview of Woodworking Saws

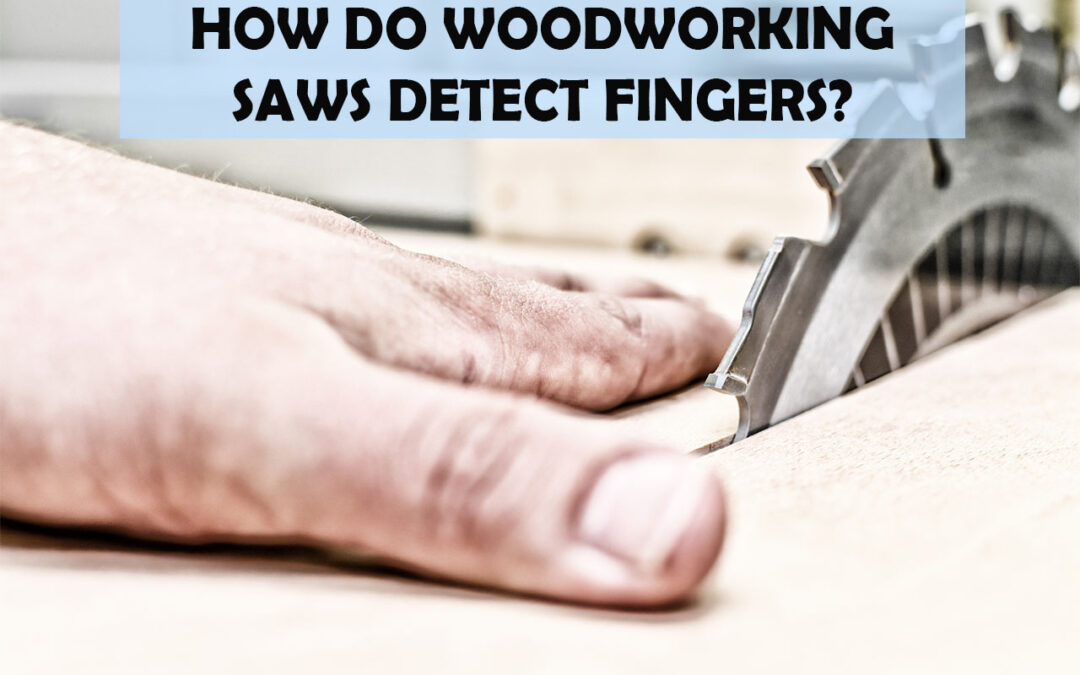

You wouldn’t want to lose any digits while woodworking, so it’s essential to know the basics of how saws can help keep your fingers safe! Learning about the different types of saws and familiarizing yourself with their proper use is one of the key steps toward successful woodworking.

The most common type of saw used in woodworking projects includes hand-held circular saws, reciprocating saws, miter saws, table saws, jigsaws, and band saws. Each type of tool has its own advantages and disadvantages for a variety of tasks. Knowing which tool to select for each job is vital to producing precise results that are both accurate and safe.

Furthermore, learning techniques such as using push sticks or feather boards can also help minimize risk when using a blade or router bit during operation. To ensure your safety even further, it’s important to understand how these tools detect fingers before starting a project. This knowledge will not only give you peace of mind but also ensure that you get the best possible results from your work.

How Saws Detect Fingers

You may be wondering how saws detect fingers in order to prevent injury. This is accomplished through two different types of sensor systems: pressure sensors and optical sensors.

Pressure sensors detect when a finger or other body part comes close to the blade, while optical sensors use light and cameras to identify objects that come into contact with the blade.

Both types of systems have been proven effective at preventing harm from woodworking saws.

Pressure Sensor Systems

Pressure sensor systems are commonly used to detect fingers in woodworking saws, enabling them to shut off quickly if a finger is too close. These systems use inertial navigation and vibration analysis to measure the pressure of an object near the blade.

The system can be calibrated to recognize when that pressure exceeds a certain limit, indicating that there is an object near the blade that shouldn’t be there. When this happens, the saw automatically shuts down so as not to cause injury or damage to whatever item has been detected.

Pressure sensors provide a reliable way for woodworking machines to identify fingers or other objects and stop themselves immediately, keeping everyone safe while they operate. As such, they are an important safety feature on any machine with sharp blades.

Transitioning into optical sensors, these systems also play an important role in keeping users safe from harm while using woodworking saws.

Optical Sensor Systems

Optical sensor systems are the perfect complement to pressure sensors, providing an extra layer of protection when working with woodworking saws. They detect any foreign objects near the blade and alert you before it’s too late.

Designed with high-tech lasers, these non-invasive methods monitor the space around a saw blade to identify anything that may be in its path. This advanced technology can recognize fingers and other objects quickly while working at high speed, allowing for safer operation.

With its dependable performance, optical sensors provide an added layer of safety in woodworking saws. As a result, fewer accidents occur due to potential contact with the blade.

The advantages of using both pressure and optical sensors make them essential components for creating a safe environment when operating woodworking saws.

Advantages of Pressure and Optical Sensors

By utilizing both pressure and optical sensors, you can benefit from their advantages to help detect fingers and ensure safety while woodworking. Pressure sensors measure the force applied to a surface or object, while optical sensors detect movement within an area. Both offer distinct benefits that make them ideal for use in saws:

- Blade protection: Sensors are able to quickly detect an object approaching the blade and automatically shut off power before contact is made.

- Dust control: By measuring air pressure, saws with sensors are able to turn on dust collection systems when needed without manual intervention.

- Increased accuracy: With precise motion detection capabilities, optical sensors can be used to enhance precision cutting results.

- Quick response time: Pressure and optical sensors have a rapid reaction time which enables fast shutdown of the blade should anything enter its proximity.

Overall, these two types of sensing technologies provide reliable protection for users while ensuring that woodworking projects remain accurate and safe. By integrating these features into saws, manufacturers ensure that essential safety protocols are followed during operation. It’s important to also follow safety tips such as keeping hands clear of blades at all times for maximum protection.

Safety Tips

To ensure safe woodworking, it’s important to follow safety tips. Keep your hands away from the blade at all times. For example, if you’re using a saw with pressure and optical sensors, make sure to stay clear of the blade even when it isn’t in operation.

Proper maintenance of your saw is also critical for safety. This includes checking that bolts and screws are securely tightened, lubricating moving parts regularly, and making sure the power cord is not damaged or frayed.

Additionally, it’s important to adhere to any safety protocols specified by your saw manufacturer. Wear protective gear such as goggles and gloves whenever possible while operating a saw. Be aware of the location of other people in the area and keep them out of harm’s way when operating a machine.

Lastly, read through the instruction manual before use so you can become familiar with how your particular saw works. Keeping these simple measures in mind will help you avoid common woodworking hazards associated with sawing operations.

Conclusion

Woodworking saws have come a long way in terms of safety, with the ability to detect fingers and other materials thanks to pressure and optical sensors. For example, a woodworker was using their table saw when their hand grazed the blade – fortunately, the sensor detected it and shut off the motor automatically.

By taking precautions when using power tools like wearing protective gear and keeping your work area clean, you can stay safe while enjoying your woodworking projects.

Frequently Asked Questions

What are the different types of woodworking saws available?

You have a range of handheld saws available for woodworking, such as circular saws, jigsaws, and reciprocating saws. Each type has safety measures to prevent fingers from getting caught while working. Make sure you choose the right saw for the job!

How much does a woodworking saw cost?

The cost of a woodworking saw can vary greatly, depending on the accuracy and maintenance required. A quality saw with proper blade maintenance and accurate assessments can range anywhere from $50 to over $500.

How often should I inspect my woodworking saw for safety issues?

Inspect your woodworking saw regularly to avoid finger fatigue and ensure its blade is always sharp. Check for any safety issues, such as cracks or loose screws, and sharpen the blade with precision. Doing so will keep you safe while also producing beautiful results with every cut.

Are woodworking saws difficult to operate?

Operating a woodworking saw is not difficult, but it does require attention to detail and safety. To prevent accidents, the blade must be kept sharp and you should inspect the saw regularly. Doing so will help you use the saw safely and effectively.

What is the difference between pressure and optical sensors?

Power and optical sensors are both used to sense objects in a saw’s blade path. Optical sensors rely on light sources to detect the presence of an object, while pressure sensors measure changes in air pressure caused by an object coming into contact with the blade. Both types of sensors require a power source and affect the speed of the blade.